Materials and CAD Files

The equipment used in our project is entirely available online or 3D printed. We have included the links to

purchase the equipment and 3D printing filament as well as the CAD files below.

This

master spreadsheet contains all the equipment needed and how to obtain them. We detail the equipment

and

objects below.

This includes cameras, bin, spray paint for the bin, and filaments for the 3D printer.

Purchased Equipment

Links to purchase the required equipment can be found here.This includes cameras, bin, spray paint for the bin, and filaments for the 3D printer.

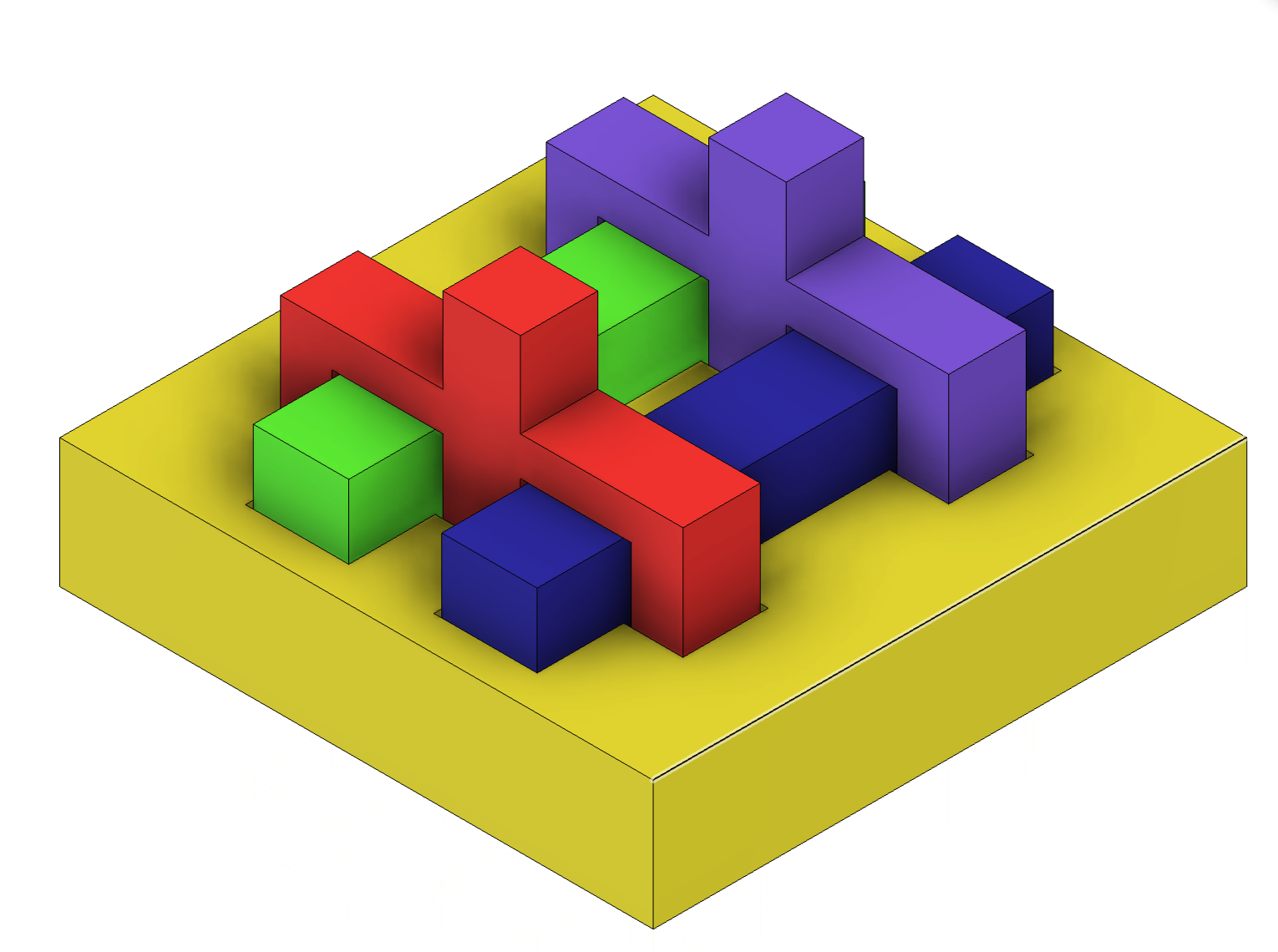

Single-Object Manipulation Objects

Refer to color/shape name and number reference sheet for the name and number assigned to each shape and color throughout our project.

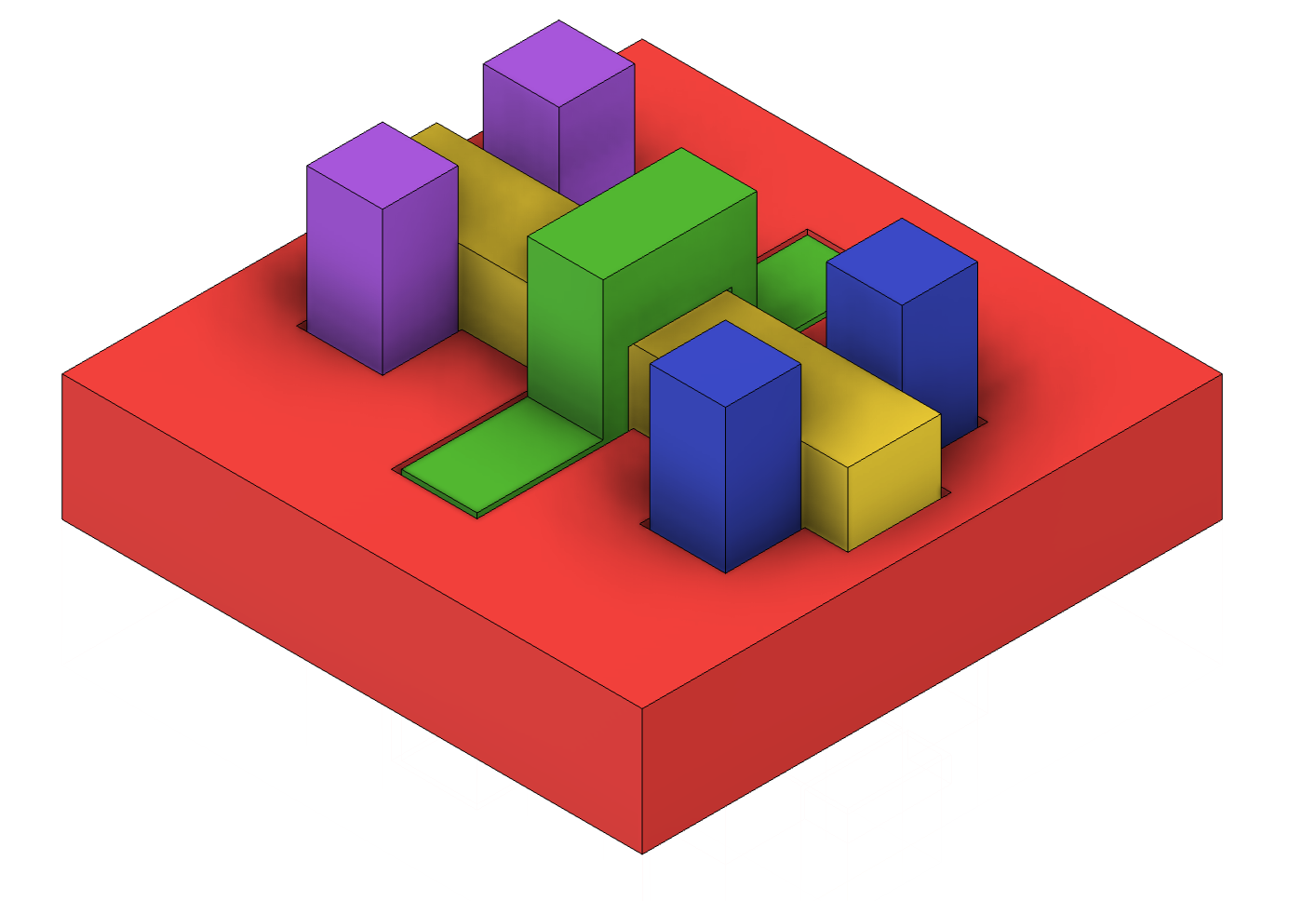

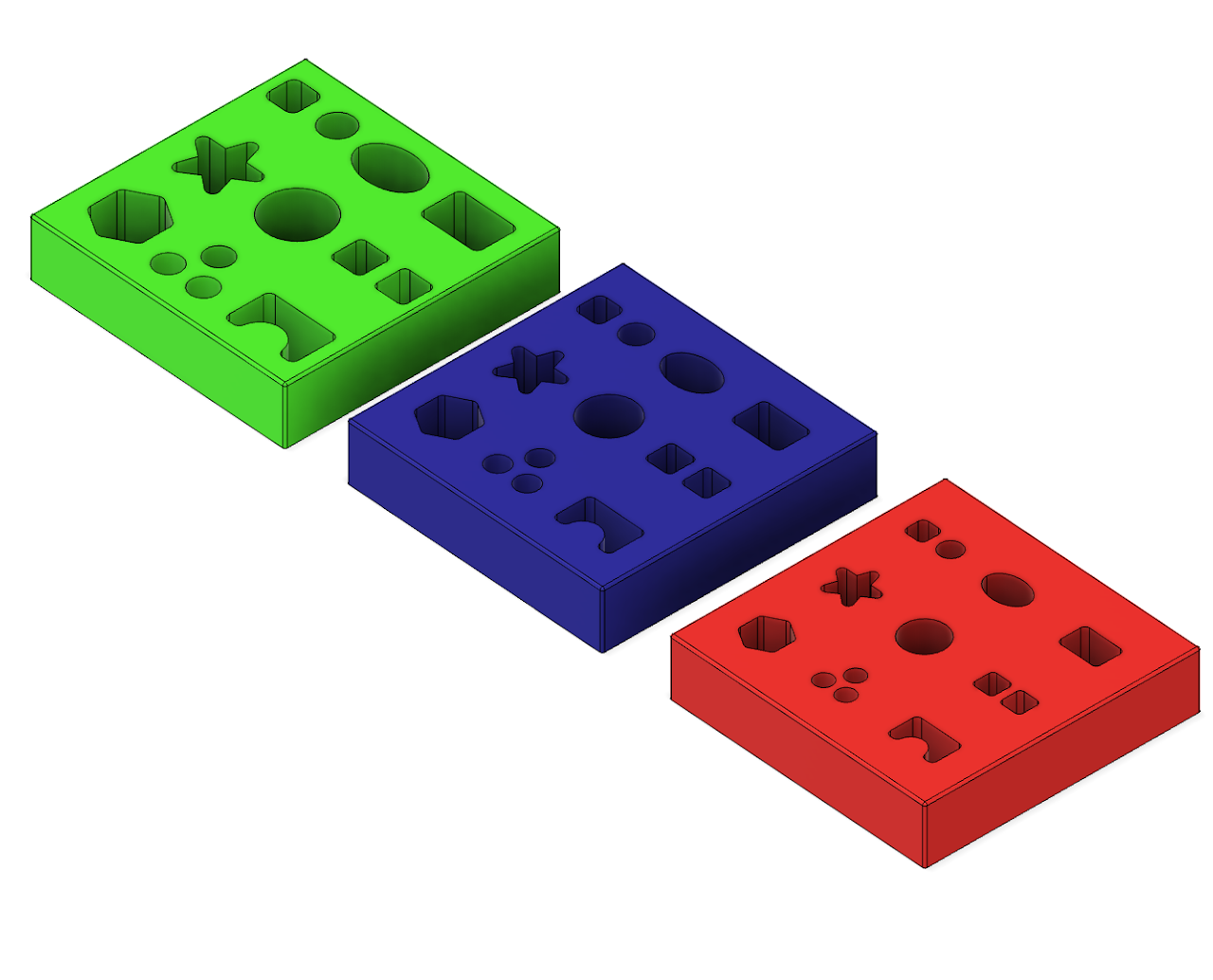

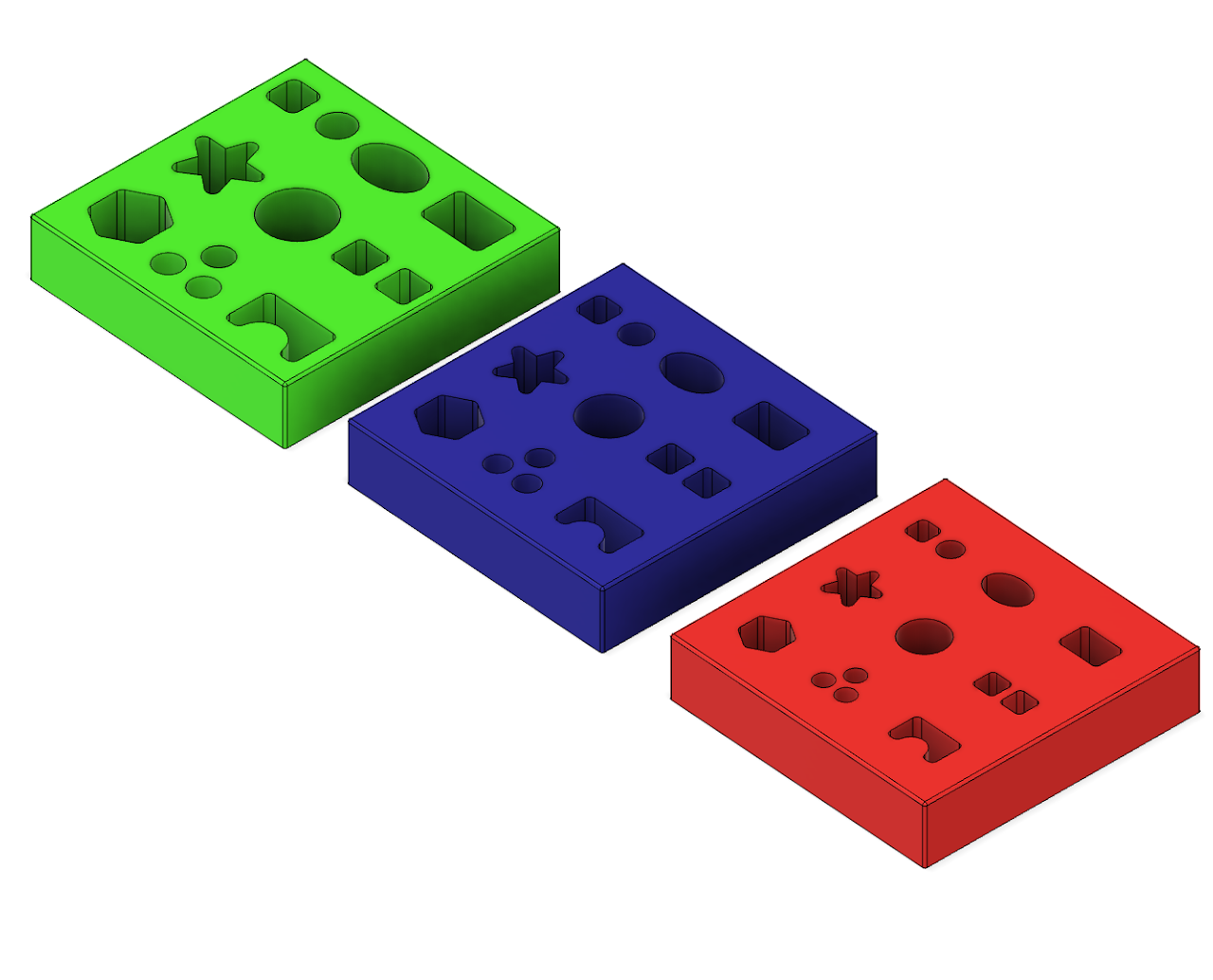

Assembly Boards

Set of 3 boards with 9 holes each. Each board has different sized holes

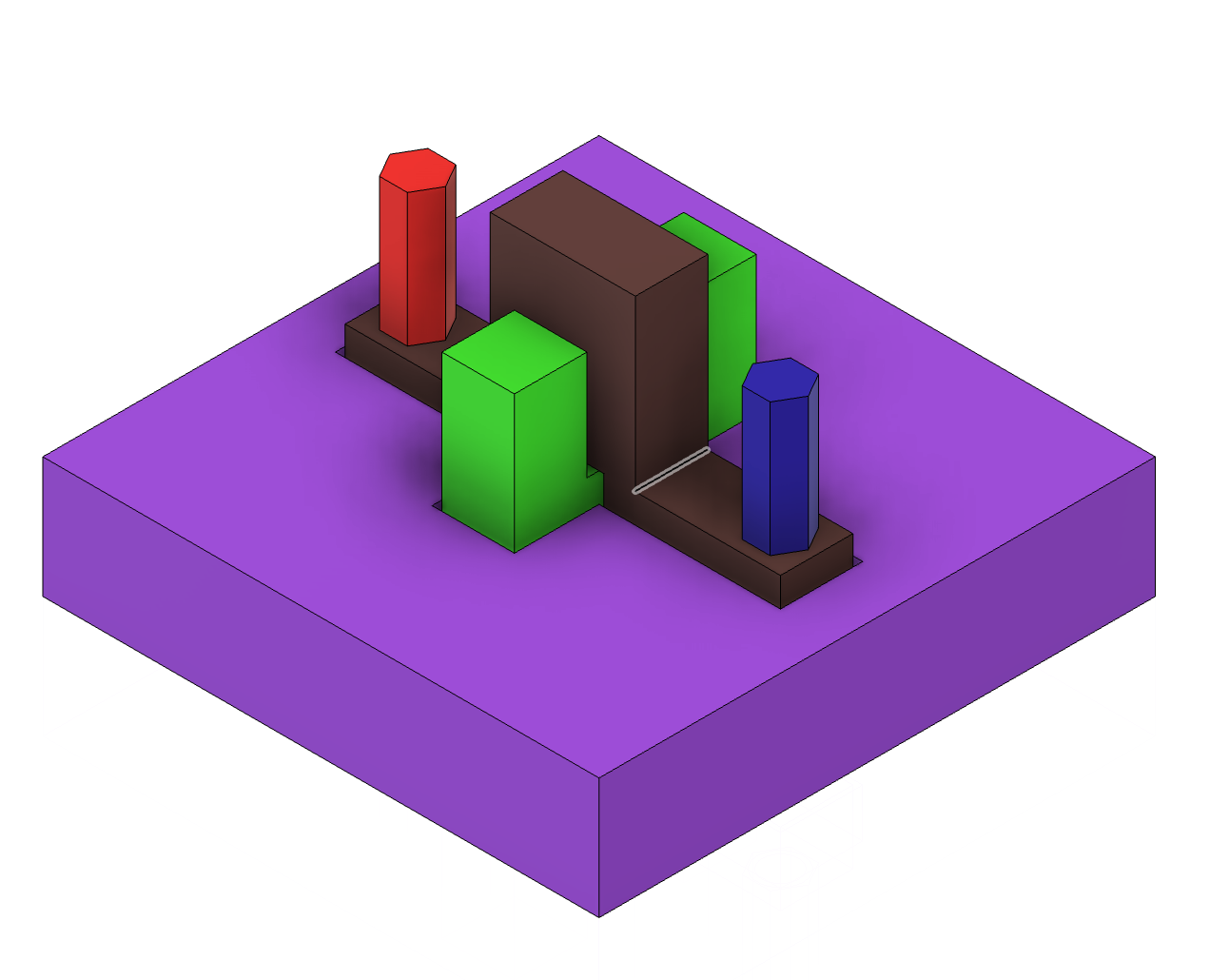

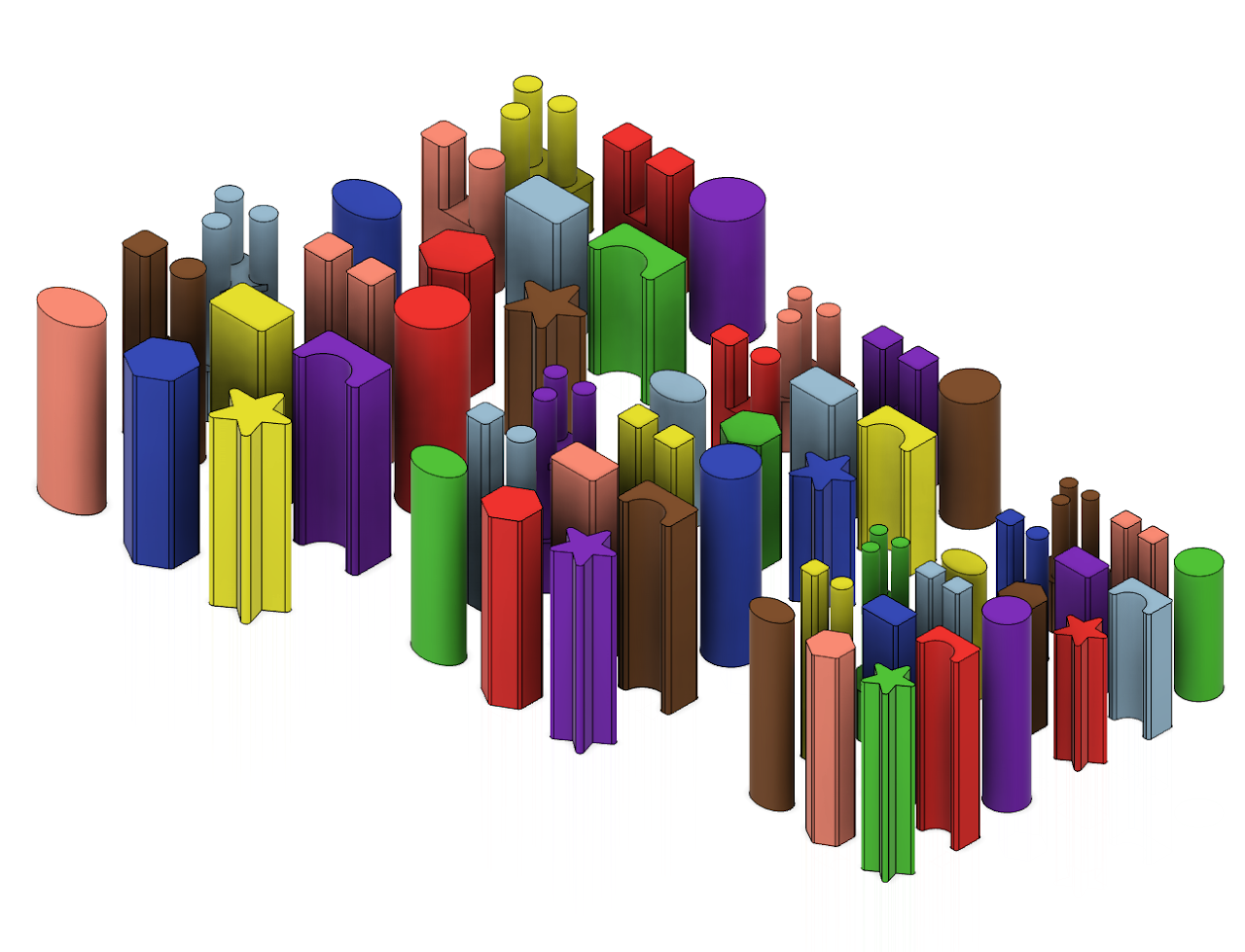

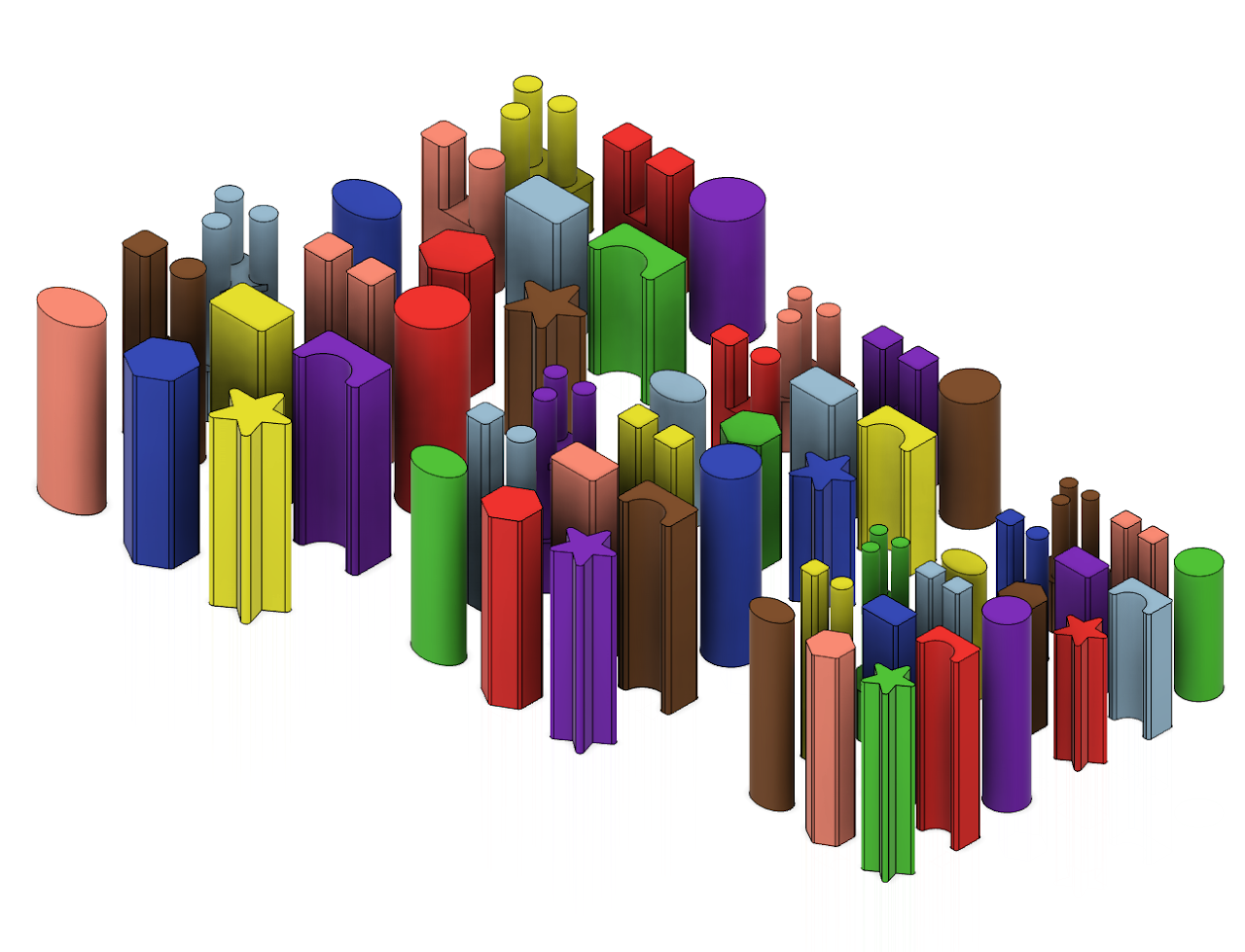

Assembly Objects

Set of pegs of three sizes, two lengths, and 9 shapes each for a total of 54 pegs.

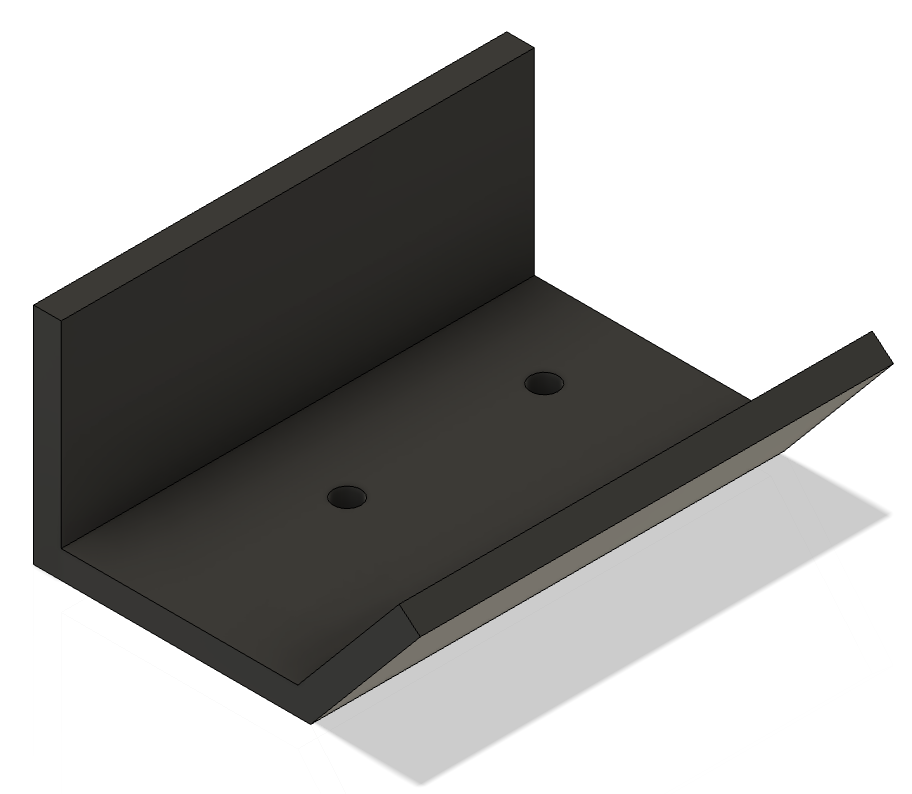

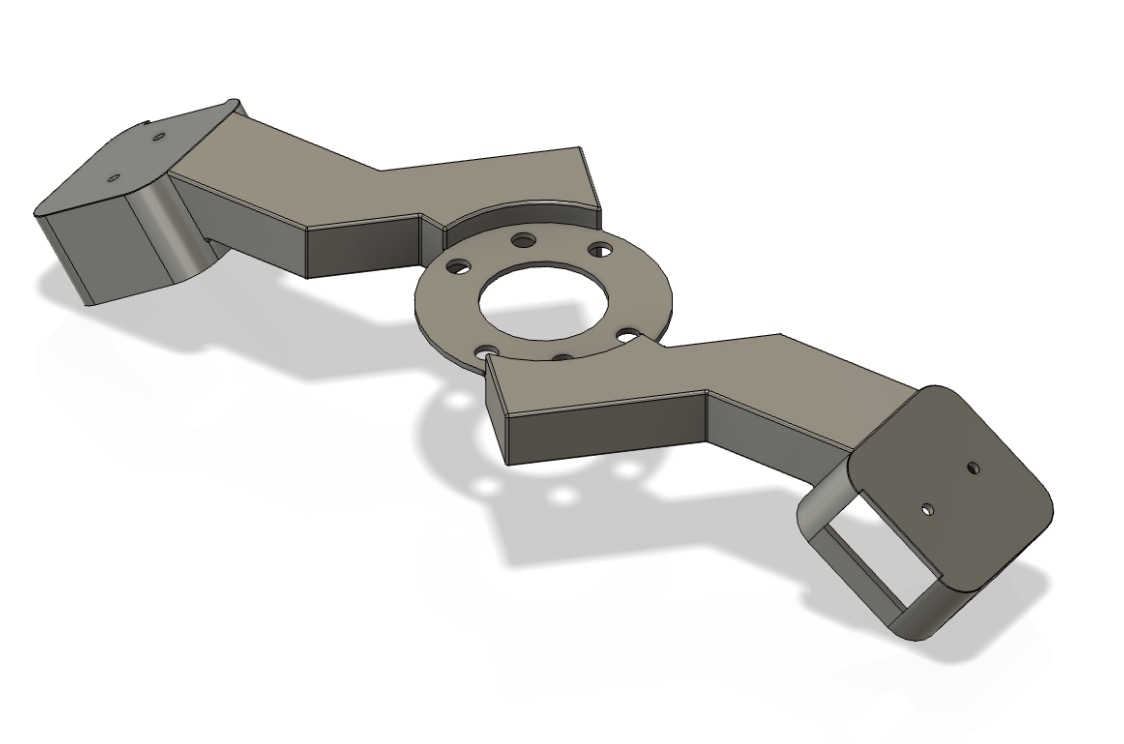

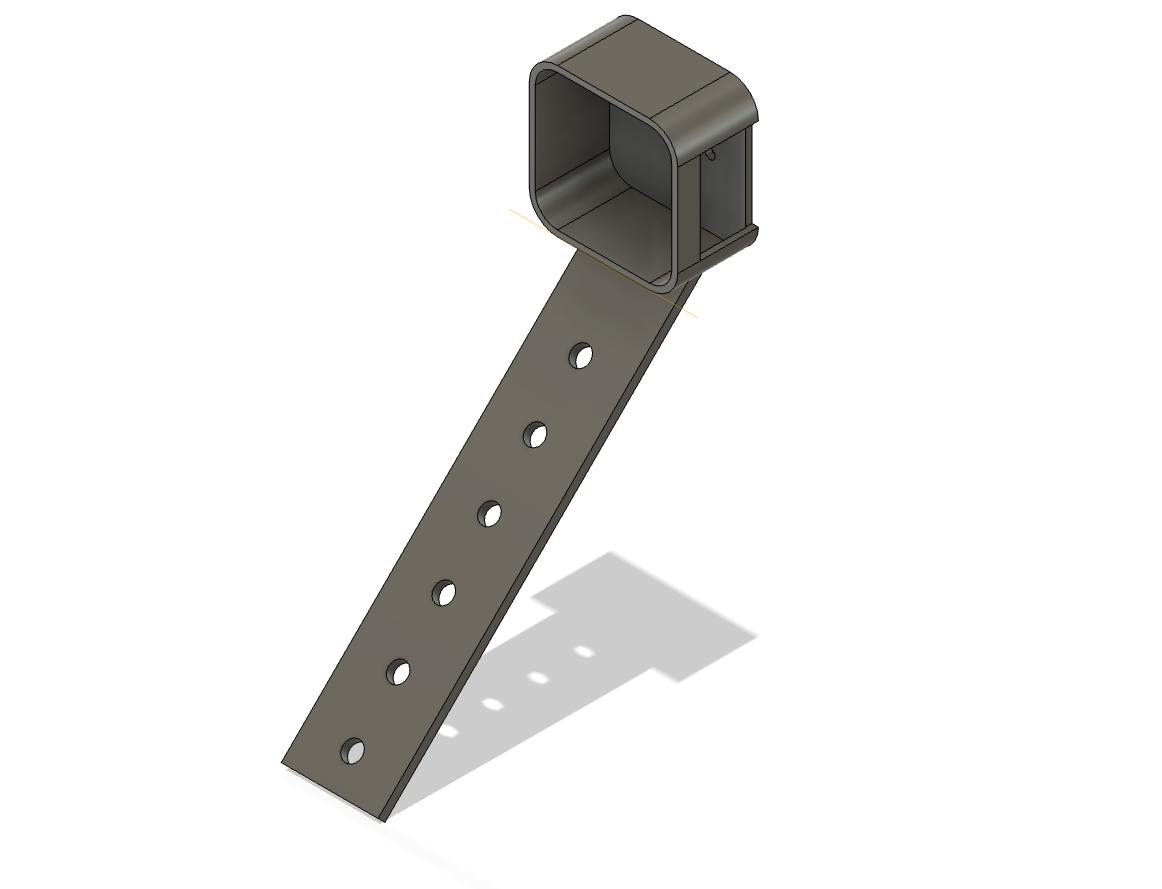

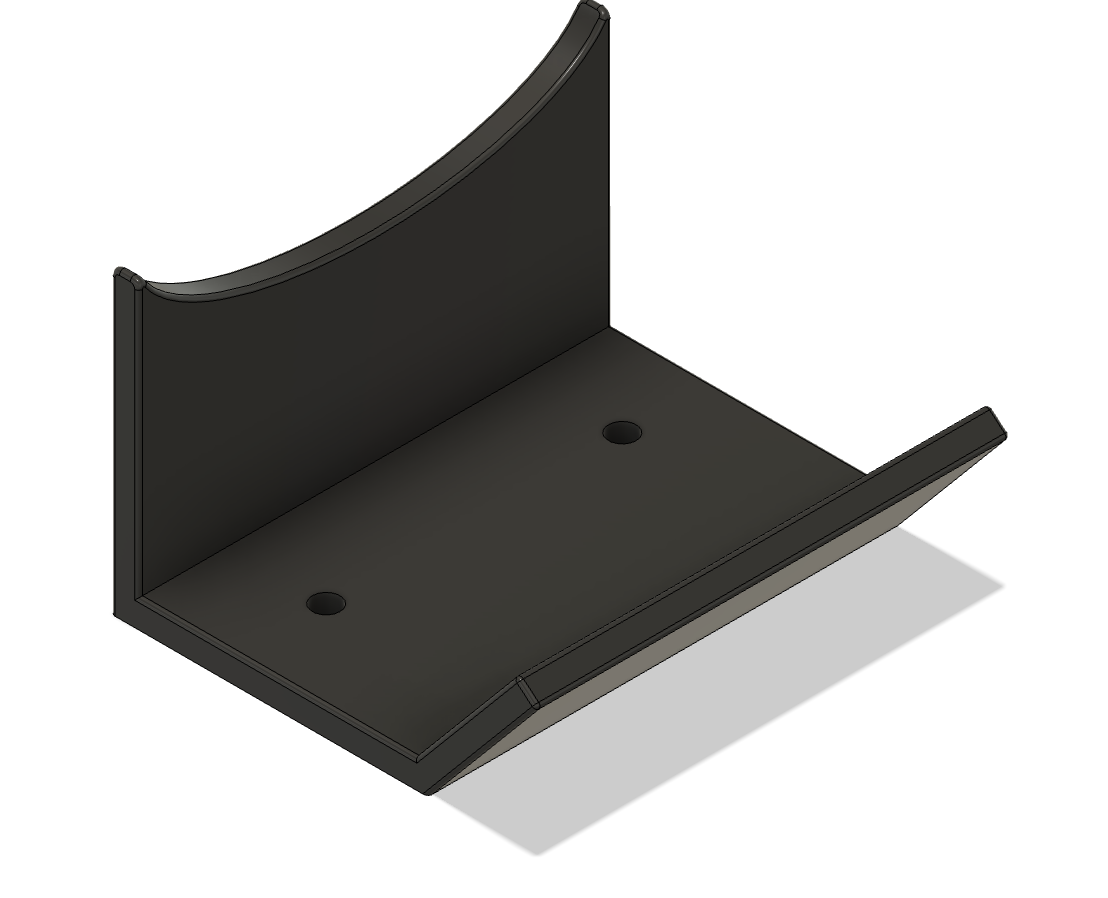

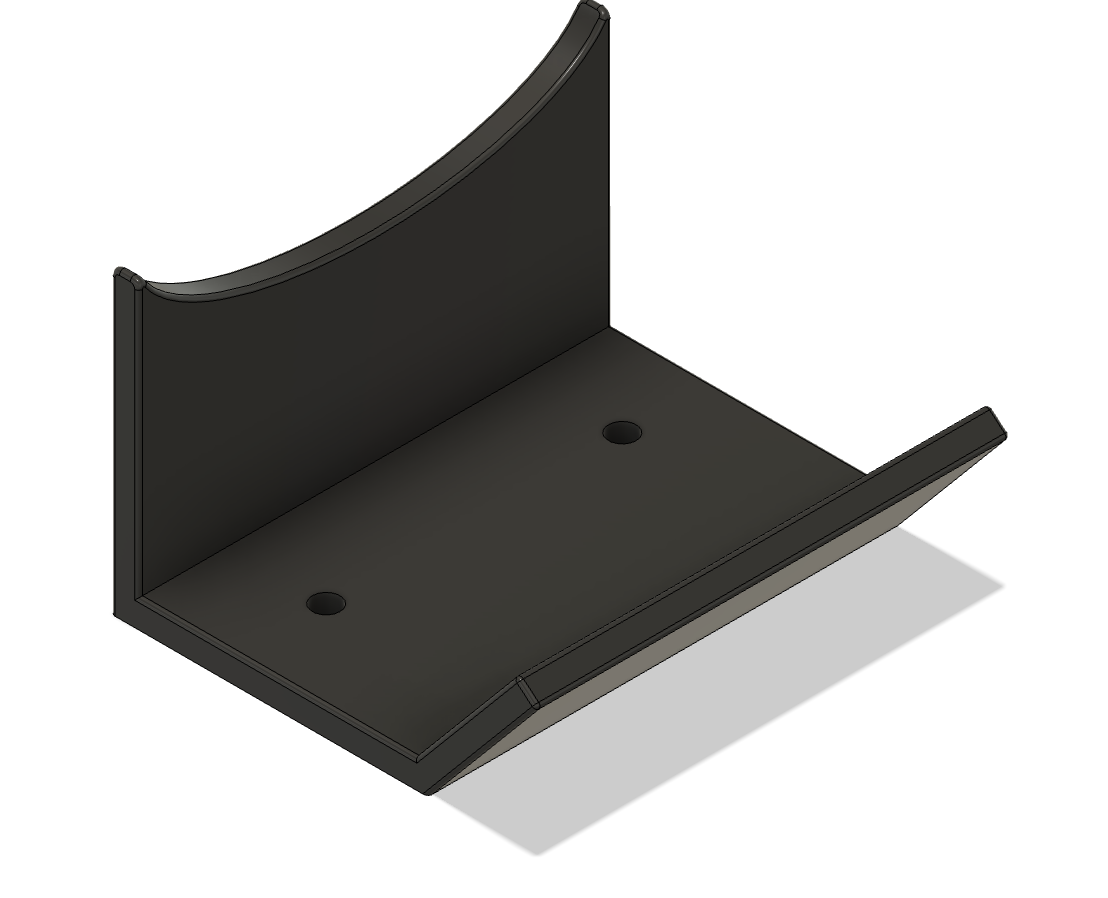

Environment Fixture

Environment reorienting fixture for Single-Object Task pieces